The first thing that comes to mind when considering a roof replacement is which type of shingles to select. However, there are other essential parts of a roof as well. One of them is underlayment. Roofing underlayment is installed between the shingles and the roof decking by roofing contractors and you need to choose the right one for you. Let’s learn more.

What Is Roofing Underlayment?

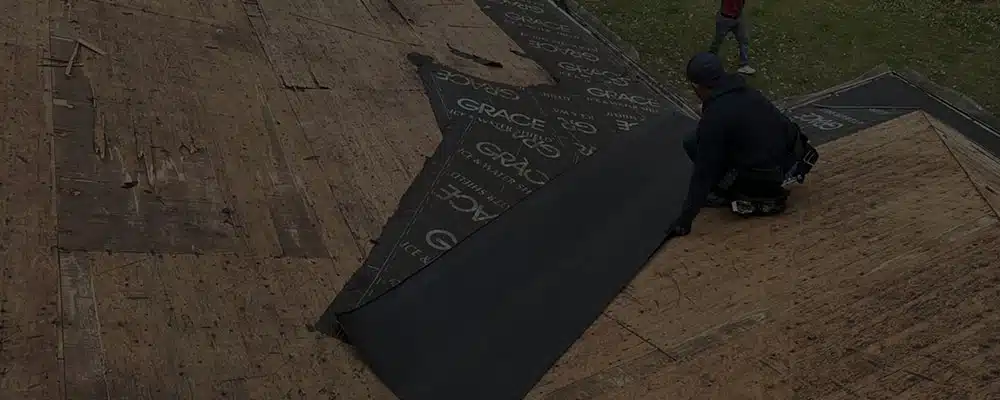

Roofing underlayment is made of synthetic fiber which is also called felt. After installing roof decking, roofing underlayment is used that serves two main purposes. It stops the moisture from entering the attic and the decking preventing mold growth and rot. It also provides additional insulation and helps in keeping your heating and cooling system efficient.

As it’s usually hidden under the shingles, most people ignore it and don’t give much thought to it. However, we explained above the importance of roofing underlayment so the right one can help increase the lifespan of your roof (shingles and roofing deck).

Can You Install A Roof Without An Underlayment?

People who want a cheap roof replacement may wonder if they can skip the installation of the underlayment and directly install shingles on the deck. Installing a roof without the underlayment is possible, but it won’t be a wise decision.

Roofing underlayment adds to the protection against water and moisture infiltration into the roof. It prevents rot to the roof deck. So, if it’s not present, the shingles won’t be completely effective in stopping moisture from getting into the roof and causing mold, rot, and other problems.

So, a roof installation without the underlayment will save you money, but the roof will sustain moisture damage sooner than later and you will have to spend money again on repairs and a replacement.

Types Of Roofing Underlayment

Three major types of roofing underlayment are used. You’re not limited to using only one type of roofing underlayment. You can use a waterproof option in leak-prone areas and install a cost-effective underlayment in other areas.

Asphalt-Saturated Felt Roofing Underlayment

Before the arrival of the two newer types, asphalt-saturated felt, or simply felt paper, remained the only roof underlayment option. It still is a popular and the most cost-effective underlayment option.

It’s made with cellulose, polyester, or asphalt in various quantities. It has another base layer for water resistance. This makes felt paper water-resistant. However, it’s not completely waterproof.

For better water resistance and even waterproofing, other two types of roofing underlayment are used which we will explain after this one. However, paper felt is still extremely popular because it provides adequate water protection at an affordable cost.

Asphalt-saturated felt comes in two different weights. The first one is No. 15 felt which means 15 pounds per sq. ft. and the second is No. 30 felt which is 30 pounds per sq. ft.

The No. 15 variant is commonly used for roofing and would be fine with medium-level protection like a shed. However, if you want to install paper felt for your house, then you must choose the No. 30 felt for better protection against moisture. Moreover, you can use multiple layers of paper felt to improve the protection factor.

But keep in mind paper felt itself is the heaviest type of roofing underlayment so you should make sure that your roof decking can withstand the weight of multiple layers of paper felt and the type of shingles you will use.

Moreover, using multiple layers will also increase the cost of the underlayment. If you’re spending enough money, you should also consider other types of roof underlayment because they are better at moisture protection than paper felt.

Rubberized Asphalt Roofing Underlayment

As the name suggests, rubberized asphalt roofing underlayment is made of rubber polymers and asphalt in various quantities depending on the manufacturer. Anyways, it’s the best quality of roofing underlayment there is, at the time of this writing.

Unlike asphalt-saturated felt, rubberized asphalt is waterproof. This means it completely stops water from entering the roof given that it’s installed correctly and it hasn’t passed its lifespan. If you need the highest level of water protection for your roof, rubberized asphalt is for you.

Apart from being waterproof, it’s a repairable material. If a part of the underlayment is damaged, the shingles from that area will need to be removed and the underlayment will be patched.

Additionally, rubberized asphalt comes with an adhesive backing. Therefore, you can directly stick it to the roof. This ensures that the entire underlayment is glued to the decking leaving no spot for water to exploit.

Rubberized asphalt underlayment has another advantage in that it expands and contracts without breaking. So, you can use it in regions where extreme temperature changes are seen.

We have discussed many good things about rubberized asphalt, so you will be waiting for the disadvantage. The only big disadvantage of this type of roofing underlayment is that it’s the most expensive one of the lot. Its benefits make up for the high cost, but it may not be affordable for homeowners who want to install a roof on a budget.

Synthetic Roofing Underlayment

Although rubberized asphalt is also synthetic, the synthetic underlayment made of polypropylene polyester is commonly called synthetic roofing underlayment.

Similar to asphalt-saturated roofing underlayment, it’s water-resistant, not waterproof, and ensures adequate protection against moisture. But in many ways, it’s better than asphalt-saturated underlayment. Firstly, its water resistance is considered more reliable than asphalt felt.

Secondly, due to its composition, it’s tear-resistant and more durable than asphalt felt. However, it’s less when compared to rubberized asphalt roofing underlayment, but probably more tear-resistant than it. Similar to rubberized asphalt, it can also expand and contract without cracking and is suitable for regions with extreme temperature changes.

A unique feature of this roofing underlayment is its heat tolerance. It’s probably the most heat-tolerant roofing underlayment and is recommended over rubberized asphalt for metal roofing.

For people who want an eco-friendly material, synthetic roofing underlayment is recyclable. Whenever it’s removed from a roof, it doesn’t go to the landfill.

The cost of synthetic roofing underlayment sits somewhere in the middle between asphalt felt and rubberized asphalt roofing underlayment.

Factors That Can Impact Your Choice

Climate

For regions with constant temperatures throughout the year, asphalt-saturated felt will work. However, if your region sees extreme temperature changes, then you should choose synthetic or rubberized roofing underlayment.

Durability And Waterproofing

The most tear-resistant underlayment material is synthetic roofing underlayment. But it’s not completely waterproof. For complete waterproofing, rubberized roofing underlayment is the only option to choose. It’s also a highly durable material, but it’s not tear-resistant.

Types Of Shingles

Generally, any of the three types of roofing underlayment go well with any type of shingles, but some work better with some types. For instance, asphalt felt and rubberized felt are considered better for asphalt shingles whereas synthetic underlayment is suggested for metal roofs.

Cost

From the cost perspective, asphalt-saturated felt is the most affordable option. The next one that costs more than asphalt felt is synthetic roofing underlayment. Then, there is rubberized roofing underlayment which is the costliest option.

Conclusion

Roofing underlayment has three types. You can choose the right one depending on your preference, your location, the type of shingles you’re using, and the cost. Discuss it with roofing companies Tallmadge to make a decision more easily.